Soontrue

TD300J High speed facial tissue bundle packing machine

TD300J High speed facial tissue bundle packing machine

Couldn't load pickup availability

Machine performance and feature

1. Using motion controller control, with 10 sets of servo power system, high degree of humanization, simple operation, accurate positioning, more stable operation;

2. Low energy consumption, the rated power of the whole machine is no more than 23Kw, and the normal production power is no more than 18Kw.

3. The machine design is compact, occupies a small space, easy to connect the production line;

4. Use well-known components at home and abroad, with mature and stable performance;

5. The equipment has a unique automatic material sorting mechanism, can realize the single and double row product packaging

specifications of fast switch, design space convenient maintenance;

|

Model

|

TD300J

|

|

|

Packing specification

|

Max bundle bag length

|

400mm

|

|

Bundle bag width

|

120~420mm

|

|

|

Bundle bag height

|

90~220mm

|

|

|

Packing type

|

Single layer single row 3-6 bags

|

|

|

Double row 6-12 bags

|

||

|

Double pack 12-24 bags

|

||

|

Triple layers

|

||

|

Bag material

|

M-type pre-made bags should be with air out-let holes (single layer thickness of bags: 40-60μ , diameter of holes 5-6mm), the

material can be OPP, CPP, PE (material must be double-sided heat sealing, handle hole position is through-hole, and the bag electrostatic elimination is good, no adhesion phenomenon); |

|

|

Packing speed

|

Single layer ≤25 bags/min;

|

|

|

Double layer ≤12 bags/min;

|

||

|

Three layers ≤5 bags/min.

|

||

|

Power supply

|

380V± 5%,

|

|

|

50Hz three-phase four wire + ground wire,

|

||

|

control voltage all use DC 24V;

|

||

|

Air consumption

|

About 0.6~ 0.7mpa (customer prepares the air supply by himself);

|

|

|

Power

|

Single installed power of 23KW, using power is around 18KW;

|

|

|

Safety

|

Safety mark is applied on the machine according to CE standard;

|

|

|

Bag trim-off

|

The bags will be cut off 25-30mm, which will be sucked into the waste bin automatically

|

|

|

||

|

Big touch screen(HMl) Easy for operation , clear working status indication, debugging is convenient and intuitive , multiple product parameters and formulations can be stored. |

|

|

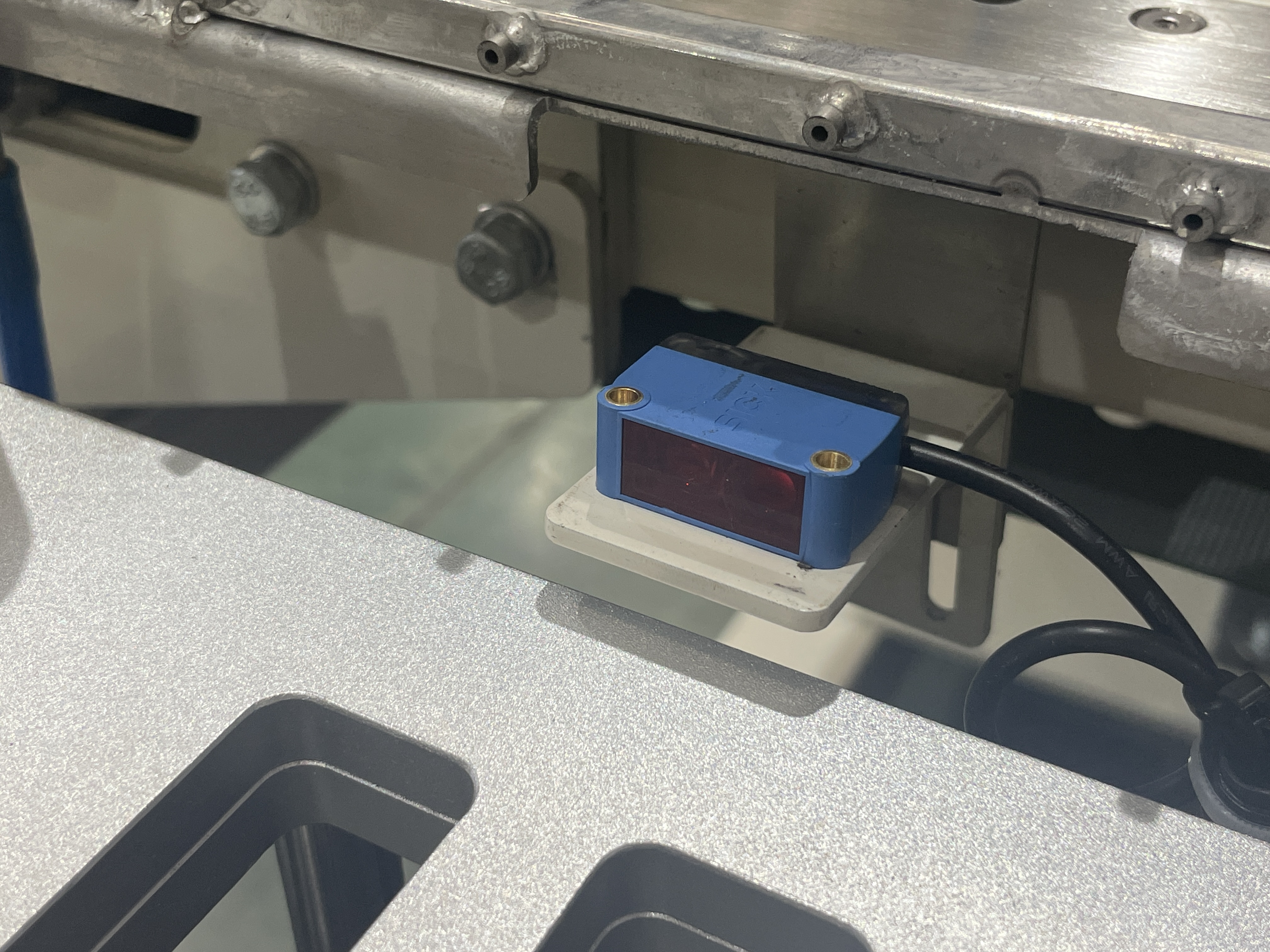

Photoelectric tracking system Photoelectric sensor automatically detect servo tracking, automatic and accurate bag feeding, automatic alarm or stop when bag loss occurs. |

|

|

Safety switch protection device Equipment mechanism with overload protection function and one-button back to the origin function. |

|

|

Automatic bag warehouse switch Equipped with 2 bag warehouse , the machine will not stop when feed the bags , and auto alarm when bags are finished on single side bag warehouse also automatically switch to the another backup bag warehouse . |

|